Put energy efficiency to work

Every watt saved is a boost to your bottom line. From building retrofits to equipment upgrades to professional training, we’re here to help Ontario businesses thrive.

Programs and incentives

Get financial and technical support to achieve your energy-efficiency goals.

See all programsFeatured programs

Retrofit Program

Instant Discounts Program

Expanded Energy Management Program

Learn how other businesses are saving

Retrofit Program

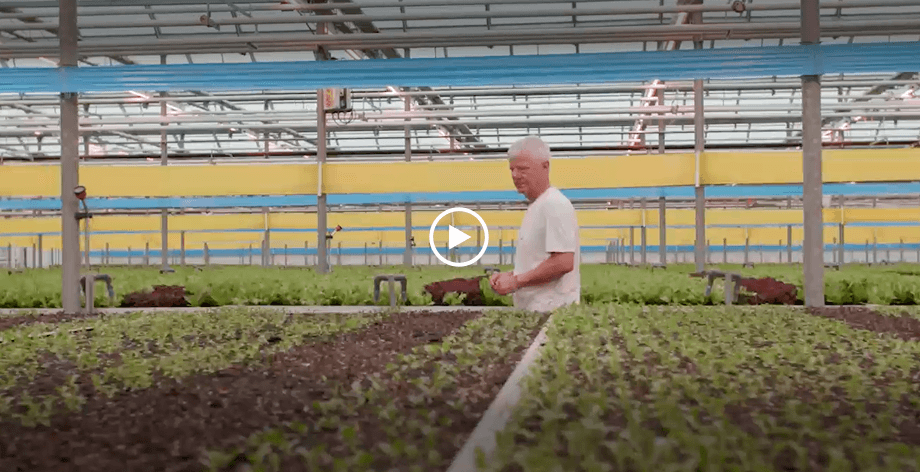

“They’re going to help guide you on the latest, greatest technology... and their incentives back it up.”

Greenbelt Greenhouse Ltd. secured $259,200 in incentives for their horticultural lighting project.

Training and support

Upskill in energy efficiency with no-cost webinars, workshops and coaching.

Check the training calendarContractors and trade allies

Deliver more value and help customers lower their energy costs.

Get startedIdentify your potential savings in our programs

The IESO’s Prescriptive Measures and Assumptions List (MAL) provides deemed energy and demand savings for the energy-efficient measures offered in the Save on Energy programs.

Learn more about the IESO’s evaluation, measurement and verification.

Sign up for simple, smart ways to cut energy use and boost savings.

* Indicates a required field

By subscribing, you are giving your consent to the Independent Electricity System Operator (IESO), 120 Adelaide Street West, Suite 1600, Toronto, Ontario M5H 1T1, to receive electronic communications regarding Save on Energy programs, events and ways to save on energy. Please read our IESO Privacy Policy so that you can understand how we collect, use and disclose any personal information you provide to us. You can withdraw your consent at any time or manage your subscription preferences here.